Product Information

GCC is a pluggable microprocessor based intellegent system controller module that provides monitoring and control for a broad range of UNIPOWER DC Power Systems deployed with either Lead Acid or Lithium Ion batteries. The GCC monitors all system parameters including: DC voltage, rectifier current, rectifier temperature, system capacity, battery parameters, and circuit breaker status.

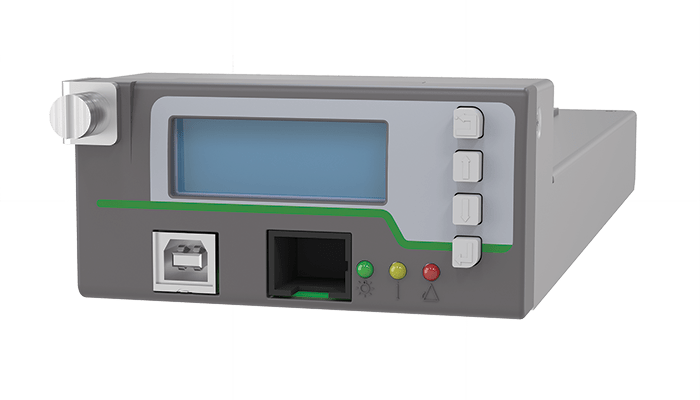

Alarm and warning notifications are indicated by front panel LEDs, and through potential free alarm contacts that allow remote signaling. External monitoring of alarms and the system is accomplished through a USB or RS232 port using PC-based PowCom™ software. The GCC has an Ethernet port allowing control over a TCP/IP network and web based support. Alarms can be mapped via SNMP traps to customer OSS (Operation Support System) platforms.

To meet individual site requirements, the GCC contains a Programmable Logic Unit that can be used to monitor and control specified requirements. This allows individual alarm routing and logic operations to be set as actions, alarms to be triggered and outputs to be activated, based on internal or external signal monitoring, comparing and processing.

THREE YEAR WARRANTY

Features and Options

- Supports Li-Ion and VRLA batteries

- User-selectable alarm parameters

- USB or RS232* Interface

- Form “C” dry alarm contacts

- Programmable alarm routing, logic unit and analog inputs

- 100 Mbps Ethernet interface with IPv4 & v6 support + built in web server + SNMP v1, v2c, v3.

- 1000-event alarm log

- Audible Alarm

- Remote configuration upgrade

- Micro SD card data logging

- Thermal protection for batteries & rectifiers

- Hot-swappable

- International standards compliance

Datasheet

Datasheet SNMP MIB Ver. 1.15 (text file)

SNMP MIB Ver. 1.15 (text file) PowCom Software Installer (zip file)

PowCom Software Installer (zip file)